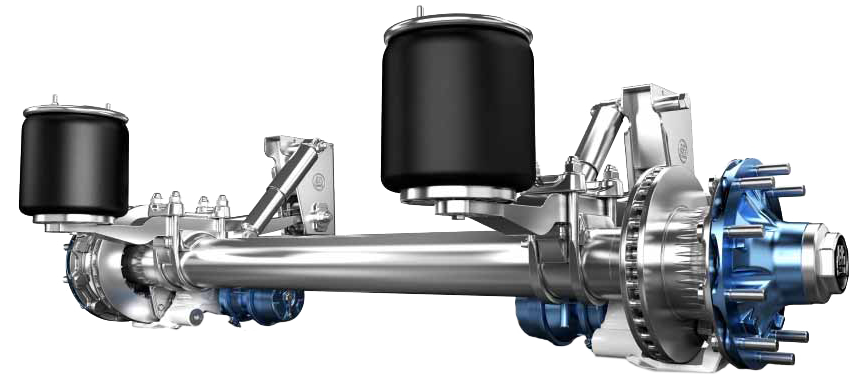

Lighter, more efficient and more cost-effective

Data improves efficiency and safety

The system not only saves energy but also prevents excess wear on the tyres. For a typical mileage of 120,000 km/year and an average pressure deviation of 10 per cent, this can prevent the emission of 655 kg of CO2 per vehicle in a year. Installing the AirSave solution reduces the costs for fuel and materials by EUR 700 for a three-axle trailer. It also reduces the risk of downtime and accidents. The drivers save time – and there are fewer pieces of burst tyre left on motorways, which have to be handled as hazardous waste.

Optimising quality and sustainability together

Suppliers who work with BPW also commit to the RoHS EC Directives and REACH Regulation, which prohibits the use of hazardous substances. The company’s supplier contracts and terms and conditions of purchase have also included a section on children’s rights/child labour since 2019, which requires partners to agree to recognise the rights of children and refrain from using child labour in the performance of their services.

Quality assurance through auditing

Manufacturing and assembly

Using local resources